Event technology

Event-

technology

static – construction – consulting

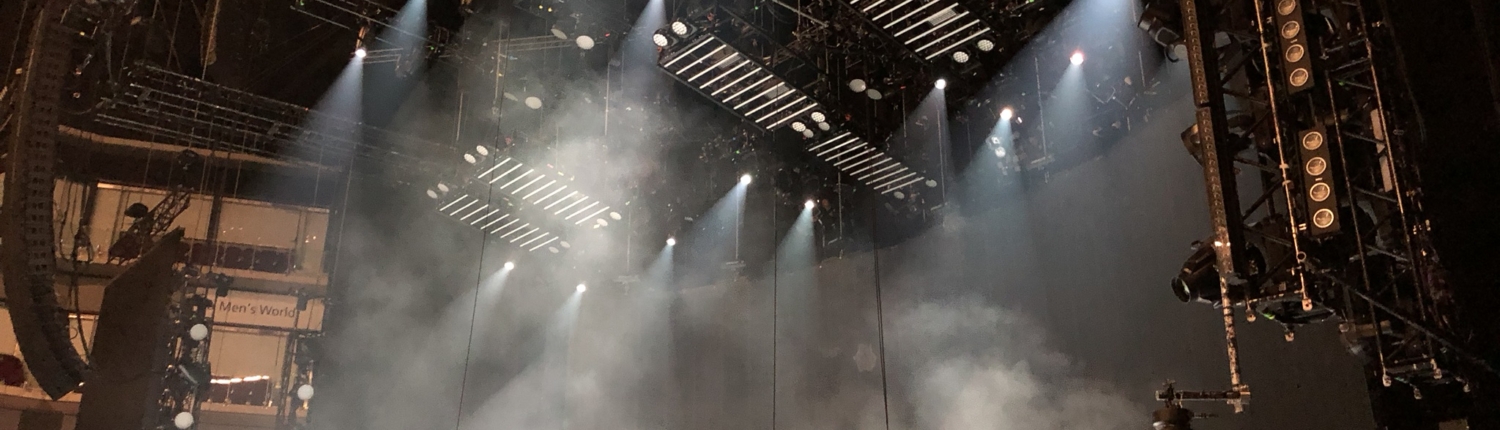

Engineering services focusing on event technology require a detailed knowledge of the industry and its processes. Our customers are the service providers and agencies of the industry that are directly involved in the building construction. In addition to the obvious safety aspects (e.g. structural safety), handling and weight are often decisive parameters in project realization. Assembly and dismantling times, loose parts and transport dimensions are only a small part of the factors to be considered for excellent products for use in event technology. We consult, engineer and calculate first-class products together with our customers or take care of subareas of the development. But also when the finished products are used, we are the partner for structural safety and stability proofs. In use at concerts and trade fairs, at festivals and company events. We take care of safety and the necessary proofs.

Data transfer for structural analysis:

(Braceworks, Production-Assist, AutoStage Analysis, SCIA Engineer, Dlubal RSTAB & RFEM etc.)

We take over data from all common industry software. By external or own converters we are able to take over all data from framework systems for our proofs.

Event technology:

- Product development

- Rigging

- Aluminium trusses

- Ground support

- Trade fair booth made of wood

- Trade fair booth made of metal

- Theatre technology

- Set structures

- Special constructions

- Stage Barriers

- Stands

- Flyware (loudspeakers, LED, etc)

- Temporarily structures

Your advantages through a data transfer:

When statico Ingenieurgesellschaft mbH was founded, new thinking and innovations in working methods and tools were the top priorities. Over the last decade, Vectorworks has become the most widely used CAD software for technical planning in event engineering. It is therefore no wonder that statico Ingenieurgesellschaft was the first engineering company in the industry to invest in Vectorworks to ensure the loss-free exchange of information.

following this, close cooperation grew with the developers of the structural analysis module Braceworks for Vectorworks, in which statico Ingenieurgesellschaft continuously participated in the beta test status with consulting and comparative calculations between established calculation systems and the results from Braceworks. After only a short time, it became apparent that the results matched, whereupon the first projects from planning to realization, including static calculations, were carried out with Braceworks.

Due to the close cooperation with the developers of the new Vectorworks add-on Braceworks, the engineers of statico were able to support the development of Braceworks already in the beta test phase. The efficiency resulting from combining technical planning with Vectorworks Spotlight and evaluation with Braceworks quickly became apparent. Already during the planning phase, parameters such as truss utilization and suspension point loads can be continuously checked. There is no longer any need to process the intermediate planning statuses and hand them over to the separate structural engineer in order to obtain initial preliminary results and align further planning with them. Interim statuses and changes are monitored by the planner himself. Thanks to the regulated data transfer, the final structural analysis can then be carried out by the experienced structural engineers without any complications. Time-consuming and risky intermediate steps are a thing of the past.

At the Eurovision Song Contest 2017, Vectorworks & Braceworks, together with statico Ingenieurgesellschaft, were able to set a milestone in technical planning. A complex system of 735 rigging points, 3300m trusses, 1816 lighting fixtures, 212 tons of suspended material, 112 CyberHoist chain hoists and a more than 30m large textile freeform above the stage was implemented.